KNITTING:-

KNITTING:-

Earlier I have discussed about the different process of manufacturing the fabric with the help of different types machines (handloom, powerloom , semi-automatic, automatic, shuttle, shuttle lessloom and weaving machine) using , their motion , primary, secondary and auxiliar which are explained in detail in my all post.

Now here I would like to doscuss about the other process of fabric which is very common and use ful to textile industry, it us KNITTING PROCESS, its details of machinary and prosuction, and different types of knitting fabric, & machines are coming one by one in my next post, if any find it useful them then follow me on the above-mentioned link.

Knitting machine an over view:-

A knitting machine is a device used to create knitted fabrics in semi or fully automated fashion.

There are numerous types of knitting machine ranging from simple spool or board templates with no moving parts to highly complex mechanism controlled by electronics. All however produce various types of knitted fabrics usually either flat or tubular , and of varying degrees of complexity. Pattern stitches can be selected by hand manipulation of the needles or with push buttons and dials , mechanical punch cards or electronic pattern reading device and computers.

PROCESS OF KNITTING:-

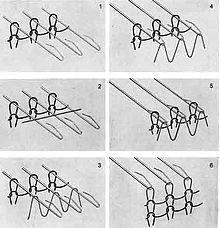

Early flat bed stocking frames had low carbon steel beared needles where the tips were reflected and could be depressed on to a hallow closing the loop. The needles were supported on a needle bar (bed) that passed back and forth, to and from the operator. The beards were simultaneously depressed by a pressure bar. These are the basic six (6) steps in knitting.

1) The Needle bar goes forward the open needle clear the web.

2) The weft thread is laid on the needles.

3) The weft threads falls loosely.

4) The needles-bar draws back , the weft is pulled in open needles.

5) The needles-bar draws back , the pressure bar drops , the needle loop close and the weft is drawn back through weft.

6) The needle open , a new row has been added to the web which drops under gravity.

This basic process can still be recognised in all machine, but it has been refined a new technologies have become available.

Types of knitting machines:-

There are a lot of ways to classify knitting machine. Some sources has classified them according to its configuration such as , either flat bed or circular. In the other refrence , it’s sorted according to its fulcrum, like for example, fabric knitting machine and garment-length knitting machines. Indeed , there are many different types of knitting machines used for making many types of knitted fabrics.

Weft knitting machines:-

Weft knitting machines are used to make weft knitted fabrics by just a single yarn. Knitting in weft is more common method than warp knitting. In weft knitting the looms are knitted horizontally in circular form from left to right of the fabrics. Weft are made from a yarn fed into the circular knitting machine needles.

Warp knitting machine:-

On the other hand warp knitting is done by knitting in a zig-zag pattern along the fabrics area. While weft knitting is done by knitting across the fabrics. Warp knitting warp is accomplished by running knits through adjacent wales or column.

Ref:-https://www.textilevaluechain.in

Comments

Post a Comment