Parts used in a loom:-

PARTS USED IN LOOMS:-

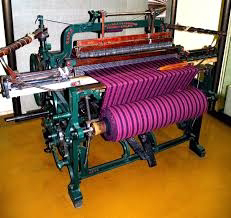

As we have already discussed about the functioning of a loom and handloom in previous article now I am going to explain about the loom parts which are generally used in loom and are essential for weaving. As we all know that a LOOM is a machine used to weave a fabric (textile) . The basic purpose of any loom is to hold the warp under tension to facilitate the interweaving of the weft threads . The precise shape of loom and its mechanism vary , but basic function is same .

The important parts of a loom are (1) Slay (2) Shuttle (3) Shuttle box (4) Picker (5) Reed (6) Warp beam (7) Back beam (8) Breast beam (9) Cloth beam (10) Heddles (heald wire and heald shaft) (11) Harness ( 12) Lease rod (13) Temple.

The actual place of these parts we have to understand about the path of warp from weavers beam to cloth roller.

The above diagram shows the actual passage of warp and different part used in at their right place. Ref by textile school.

The warp after leaving the weavers beam 1 passes through over two bars 2 and 3 by bracket fixed at each end of the loom . One half of the warp now passes under the back lease rod 4 and other half passes over this rod. These rod on which warp passed under the lease rod pass over the front lease rod 5 and from over the back lease rod pass under the front lease rod . Therefore the warp is completely divided in two layers as it passes through the lease rod, and facilitates the straightening of any warp end which may break and entangled before they reach the heald 6 & 7. The lease rods also assist in forming even shed .

The passage of warp threads through lease rod reduces the friction to warp. Leaving the lease rods , the warp end next pass through healds , odd numbered pass through the front heald 7 and the even numbered end pass through heald 6 . The healds consist of heald wires with eyes at the centre through which the warp ends are passed , this warp ends being controlled for their upward and downward movement when shed form at the time of weaving (for weft insertion). The warp ends next pass through reed 8 , this being compromised of a flat wired comb with the teeth secured at both end. Usually two ends passes between one tooth and the next-this, space being termed “DENT". In the figure two warp ends are represented as being in the same dent.

Although point 9 is what known as the “cloth fell" . It may be considered as the point where the warp and weft becomes cloth, because, it is at this point where the last pick of weft , which was left by the shuttle becomes beaten up. Passing forward, the cloth is held at each side by a temple 10 which holds the cloth pass over the breast beam/front rest 11 . Partly around the sand or emery roller K over a steel roller or tension rod L and then on to the cloth roller M. This completes the passage of warp from weavers beam to cloth roller as fabric made ready.

https://www.textileschool.com

Important parts of loom:-

As earlier I have given the name of parts which are vrey important in loom to produce the fabric in weaving process. Now a brief explanation is given as follows respectively;

(1) SLEY OR LAY:-

It is made of a wood and consist of the sley race board, reed and reed cap place over the reed by holding the reed firmly at both the vertical frame innerside, and two shuttle boxes at other side of frame fixed with sliding picker on the spindle in it. This picker gives the shuttle to traverse from one side of the fabric to other side through warp shed for completion of pick. Sley is responsible to pushing the last pick of weft to the fell of the cloth by means of beat up motion with the help of reed. The sley moves faster towards the fell of cloth and moves slower when moving backward. This unequal movement is known as “Eccentricity of sley" . It is needed to order to perform the beat-up and also give sufficient time for passing shuttle through the warp shed. The beat-up of the last pick of weft is accomplished through a metal reed attached to the sley.

Image of a pit loom showing a weaver holding the sley with left hand with reed cap and shttle box fitted in the sley both side end.cRef by textile magzine.

(2) SHUTTLE: -

It is basically a weft carrier and helps in interlacement of the weft with the warp threads to form a fabric. The shuttle which made of wood passing from one end of the shuttle box to another box. It travels along the wooden slay race and passes between the top and bottom layer of warp sheet (shed).

The shuttle enters a shuttle box after after passing through the warp shed leaving the weft yarn for beat-up. A shuttle normally out app 0.45 kgs.

Image of shuttle with weft. Ref by textile tutorials.

(3) SHUTTLE BOX:-

It is the housing for the shuttle and is made of wood . It may also accomodate the picker and spindle in it. The top and side of the box of the box towards the slay race are open . The shuttle dwells inside the box for the intermediate period between two successive pick.

(4) PICKER:-

The picker is piece made either of leather or synthetics material. It may be placed on spindle grooves in the shuttle box . It is used to drive the shuttle from one box to another. It also sustains the force by the shuttle while entering the box.

It is a metallic comb , that is fixed to the sley with a reed cap. This reed is made of a number of wire is known dent. Each dent can accommodate one , two or more warp ends. The count of Reed is desired by the number of dents in inches. The reed performs a number of functions which are enlisted as follows;

1) It pushes the lastly laid pick of weft to cloth fell.

2) It helps to maintain the position of the warp threads.

3) It acts as a guide to the shuttle, which passes from one end of the loom to the other.

4) It determines the fineness by the cloth in junction with the heald.

5) It determines the openness or closeness of the fabric. There are various types of reed such as ordinary reed, guaze reed expanding reed and V reed.

https://www.textileschool.com

Comments

Post a Comment