WARP KNITTING:-

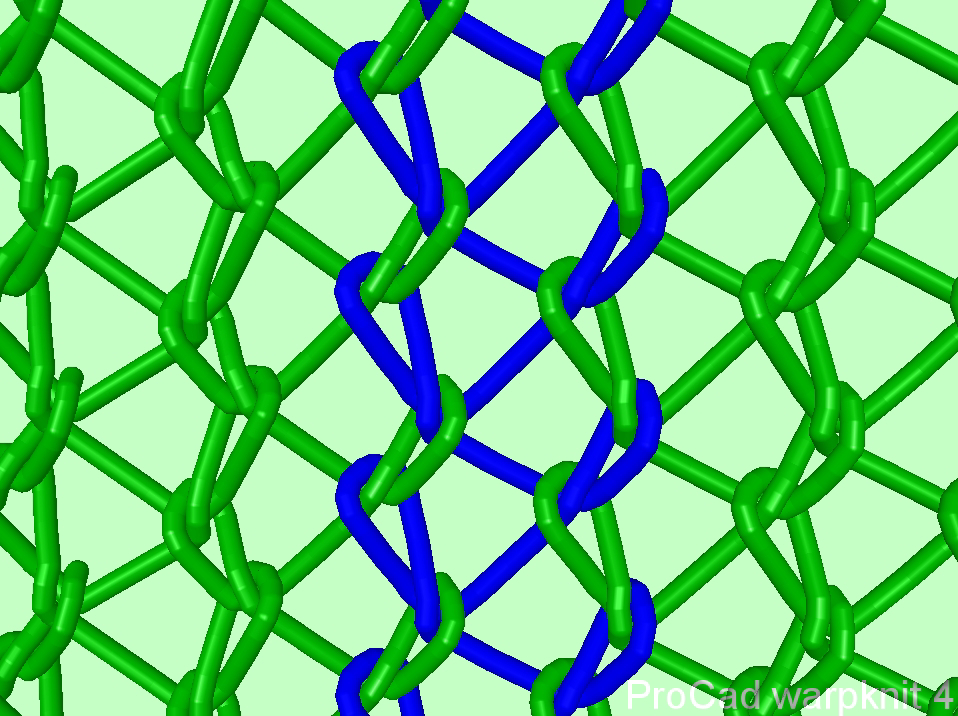

Image of warp knitting.

Warp knitting represents the fastest method of producing fabric from yarns. Warp knitting differs from weft knitting in that each needle loops its own thread. The needles produce parallel rows of loops simultaneously that are interlocked in a zigzag pattern. The fabric is produced in sheet or flat form using one or more sets of warp yarns. The yarns are fed from warp beams to a row of needles extending across the width of the machine. Two common types of warp knitting machines are the Tricot and Raschel machines. Raschel machines are useful because they can process all yarn types in all forms (filament, staple, combed, carded, etc.). Warp knitting can also be used to make pile fabrics often used for upholstery.

WARP KNITTING STRUCTURE:-

warp knitting structureWarp knitting is defined as a stitch forming process in which the yarns are supplied to the knitting zone parallel to the selvedge of the fabric, i.e. in the direction of the wales. In warp knitting, every knitting needle is supplied with at least one separate yarn. In order to connect the stitches to form a fabric, the yarns are deflected laterally between the needles. In this manner, a knitting needle often draws the new yarn loop through the knitted loop formed by another end of the yarn in the previous knitting cycle.

A warp knitted structure is made up of two parts. The first is the stitch itself, which is formed by wrapping the yarn around the needle and drawing it through the previously knitted loop. This wrapping of the yarn is called an overlap. The diagram shows the path taken by the eyelet of one yarn guide traveling through the needle line, making a lateral overlap (shog) and making a return swing. This movement wraps the yarn around the needle ready for the knock-over displacement.

The second part of stitch formation is the length of yarn linking together the stitches and this is termed the underlap, which is formed by the lateral movement of the yarns across the needles.

The length of the under lap is defined in terms of needle spaces. The longer the underlap, the more it lies at right angles to the fabric length axis. The longer the underlap for a given warp the greater the increase in lateral fabric stability, conversely a shorter under lap reduces the width-wise stability and strength and increases the lengthways stability of the fabric.

The length of the underlap also influences the fabric weight. When knitting with a longer underlap, more yarn has to be supplied to the knitting needles. The underlap crosses and covers more wales on its way, with the result that the fabric becomes heavier, thicker and denser. Since the underlap is connected to the root of the stitch, it causes a lateral displacement in the root of the stitch due to the warp tension. The reciprocating movements of the yarn, therefore, cause the stitch of each knitted course to incline in the same direction, alternately to the left and to the right.

In order to control both the lateral and longitudinal properties, as well as to produce an improved fabric appearance with erect loops, the second set of yarns is usually employed. The second set is usually moved in the opposite direction to the first in order to help balance the lateral forces on the needles. The length of the underlap need not necessarily be the same for both sets of yarns.

Ref:-https://www.textileschool.com

WARP KNITTING MANUFACTURE:-

Warp knitting is the least common form of knitting. Instead of the stitches running horizontally across the knitted piece of fabric, like in weft knitting, they run vertically down the fabric. They are knitted in continuous widths, meaning that long pieces of fabric are made and then the garments are cut out, much like it would be done with a woven piece of fabric. It is the most complex form of knitting; this is why it is seldom used. Warp knitting requires the use of a machine, it cannot be done by hand.

Warp knitting is generally used for knitting fibres such as Aramid, Carbon and glass as it puts less pressure on them and uses more careful handling than weft knitting. It is the fastest method of producing fabrics from yarns as one of the main differences from weft knitting is that each needle has its own yarn which produces a zig zag chain, these chains are then all interlinked to produce a fabric, bu this does mean that the width of the fabric cannot be increased or decreased like it can with weft knitting. Warp knitting is useful because it can process many different yarns that regular knitting machines cannot such as staple, filament, combed and carded. Warp knitting machines can also be used to make pile fabrics.

PROPERTIES OF WARP KNITTING:-Properties:-

(1) Less elastic than weft knitting.

(2) More run resistant than weft knitting.

(3) Denser than weft knitting.

(4) Less likes to become misshapen that weft knitting.

(5) Type and weight of yarn dictates the type of fabric that is produced.

(6) Warm to wear.

(7) Comfortable.

(8) Usually soft and drapey.

(9) Curls at the edges.

(10) Easy to sew.

END USES OF WARP KNITTING:-

(a) Historically used for blouses, lingerie and gloves.

(b)Tricot is often used for underwear.

(c) Often used as an unlined material for jackets, coats and skirts and dresses.

(d) Lace fabric and trimmings

Ref:-https://www.catwalkyourself.com

Comments

Post a Comment