HARNESS BUILDING FOR ANY JACQUARD LOOMS.

Harness and comber board:-

HARNESS:-

The figuring harness includes all the connection below the neck cord to the lingoed consist of upper and lower coupling , mail-eye , comber board, and mounting thread . The length of the mounting threads depends upon the height of the jacquard. It is generally 5' or 1.52 meters in case of 40" or 101.6 cm. wide loom and 9' or 2.74 meters in case of 160" or 4.06 meters loom from the mail eye to hook . The harness, which is tied to neck cord , passes through the comber board to the upper coupling and mail eye , then to the lower coupling and the lingoe. The harness cords should be strong and smooth to resist the friction of the comber board and jerk of the working machine.

LINGOE:-

A 'lingoe' is a cylindrical metallic dead weight with a flattened and punched or looped end to take the lower portion of the coupling. A LINGOE varies in length from 7" or 17.8 cm. to 19" or 48.25 cm. and in weight from 4 to 60 to the pound or 0.45 kilogram.

Mail Eyes and Couplings:-

Mails are made of brass, steel, galvanized iron or glass and contain three hole. The central hole is reserved for warp thread and the two outer small holes receive the 'top' and 'bottom' couplings. The coupling vary in lenght from 6" or 15.24 cm. to 9" or 22.8 cm. If a top coupling and mounting thread are to be united above a comber board , the loop is from 12.5" to 16". or from 31.75 cm. to 40.64 cm. long .

Comber Board:-

A 'comber board' is usually made of wood and is perforated to hold each mail eye exactly opposite the dent of the reed. The comber board may be solid or in strips.

(a) A strip of a comber board consist of wood from 3/4" to 1.5 " or from 1.9 cm. to 3.8. cm. thick long enough to reach across the loom, wide enough to take as many as holes as are required in one short row of hooks.

(b) Comber boards , composed of wooden slips from 1/4" to 5/16" or 0.635 cm. to 0.79 cm. thick by 1" to 3" or 2.54 cm. to 7.62 cm. broad , and held together in grooved frame, are mostly used.

(c) The number of holes in one row back to front equals the number of needles in the vertical row if the jacquard, but it is not always compulsory.

(d) When one end passed through each mail eye , the number of holes in 2.54 cm. in the reed. A comber board fixed by brackets 1.25 cm. A behind the sley, while the sley is at its back center position.

Levelling the Harness.

The arrangement for levelling the Harness may be the below or above the comber board. The long narrow levelling board is technically called a 'slabstock'. Levelling the Harness is necessary to maintain the warp threads in one line , while moving up or down. The figure 129 A is front elevation of a portion of the slabstock with the upper and lower couplings slipped over it. Fig 129B is sectional elevation of the same details , when tying has to be performed above the comber board.

In the figure , D is the mail eye ; E and F are upper upper and lower coupling; G is the lingoe. W is the slabstock with a groove X large enough to admit of the mail D. A steel wire Y is passed through the eyes of the mails D and is maintained in the groove X through the medium of a piece of cord Z. This cord is tied at regular intervals over the wire Y and slabstock W. The steel wire Y must be fixed horizontally under the comber board center with its lower edge at such a height that the mails D, when drawn against it, will be in the bottom shed line.

The slabstock is then adjusted to the loom walls and levelled preparatory to tying in the harness . When this operation is complete , the upper coupling E is threaded through the perforation in the comber board after the latter has been marked off to suit the width of the harness. The harness is next passed through the loom to the upper coupling E, which together with the harness twins are drawn to their normal tightness and then knitted. This process is repeated with each separate row of harness , until the whole is complete.

System of Harness Mounting:-

There are two methods or systems of harness mounting on jacquard looms, namely:-

(1) Norwich system , and

(2) London or French system.

The former method is however, most commonly adopted in power looms. Jacquards are supported upon the the loom framing on wooden or iron girders. A Jacquard must be capable of vertical adjustment, so that the mail eyes may be placed on their proper level.

(i) The harness are mounted through the perforation corresponds to any required fineness and each hole normally corresponds to one end of warp in the cloth. If the comber board used is finer than the harness, the extra rows of holes must be left empty .

(ii) The orders of perforation in the comber board may be 'straight', 'diagonal', or ' plain weave pattern'. The last order is most commonly adopted.

(iii) A comber board is fixed horizontal by brackets to the loom frame half-inch or 1.27 cm.behind the sley , when the crankshaft is on the back center.

(iv) The dents per inch or 2.54 cm. in the reed are determined by the number of harness cords per inch or 2.54 cm. divided by the number of harness cords which are designed to pass through each dents in reed.

(1) NORWICH SYSTEM:-

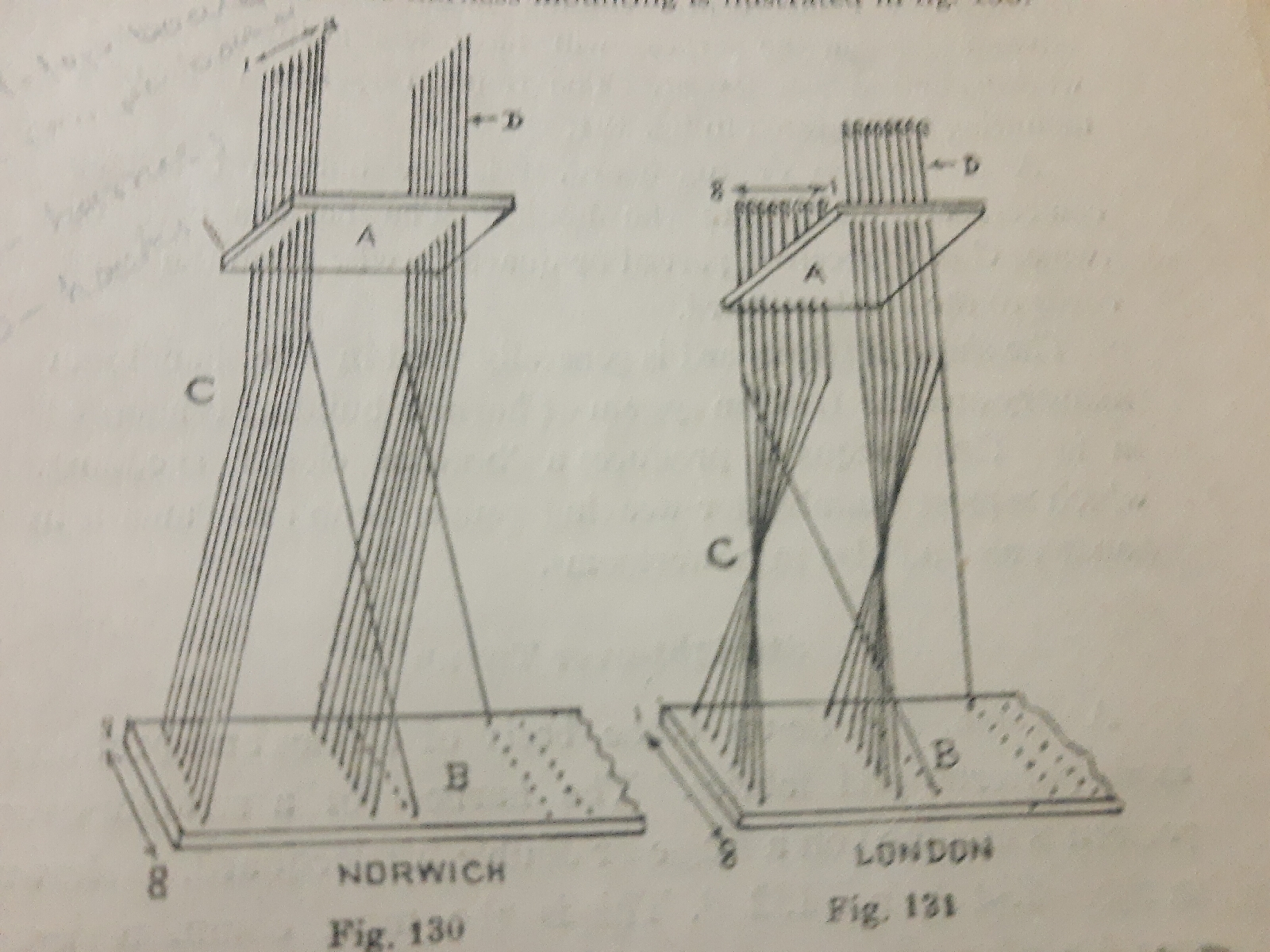

With the Norwich system , the jacquard machine and card cylinder are placed parallel to the comber board. The cards and cylinder operate either at the front above the head of the weaver , or at the back of the loom over the warp . This system is the most common in the cotton industry and the best for ordinary work as the cotton industry and the cards interfere with the light on the cloth and the warp. The Norwich system of Harness mountiñg is illustrated in fig 130.

As in figure A shows tug or top board , B , the comberboard and D the hooks. The harness C is tied up to the first hook of each row from back to front . Each harness is brought B. The number of rows of harness normally coincides with the number of hooks.

The double lift jacquards are commonly used in the power loom industry, and the Norwich system of Harness building is adopted in them . This jacquard has higher speed and lesser friction of harness cords and produces a semi-open shed, but has more swinging of harness cords.

(2) LONDON SYSTEM:-

With the London system, the jacquard machine and the card cylinder are placed at the right angles to comber board ,vso that the cylinder and pattern cards fall over either side of the loom . This system is convenient to a handloom weaver as he can watch and control the cards his seat

The disadvantage of this system is that the harness receives a quarter twist in passing from the hooks to and through the comber board causing more friction. But the advantage is that the harness will have less swinging during working and so lasts longer. The London system of Harness mounting is illustrated in fig 131.

A is the top or tug board,bB is the bottom board or comberboard and D are the hooks. The harness cords or twines C have received partial or quarter twist from the neck cords to the comberboard.

The single lift jacquard is generally used in the handloom industry and the London system of Harness building is adopted in it This jacquard produces a 'bottom closed' shedding, which for weaving guaze, Leno and damask in handlooms and also in powerlooms.

Straight-over Tie-up:-

A straight-over tue-up is the basis of all tied and produces most patterns and fabrics. The harness of a straight-over pattern is mounted on a single or double lift jacquard, as shown in fig132A and 132B . This is the most common tie-up used for all figure design which contains several or many repeats in full width of the cloth . This tue-up is not adopted in order to effect economy in cards , ad by enabling a small jacquard to weave large figure designs.

(i) The number in the line A represent the hooks in the jacquard to which the neck cords are to be attached. The comberboard B is a frame into which the perforated slips are fitted. These slips are perforated to different degrees of fineness being regulated by the number of ends per inch or 2.54 cm. required in the cloth to be woven .

Fig. 132A and 132B showing the direction of cords to be passed through comberboard slips in the board numbering from 1 to 400 hooks and cords.

(ii) The lingoes L serve the purpose of keeping the mail eyes down . MM are the mail eyes through which the warp threads are drawn in the order shown by the numbers, begining at the back left hand corner (London system). The harness is built with linen threads, from 12" to 30" , in 3, 4, 5, or more folds well varnished and polished for smoothness.

(iii) When one lingoe has been connected to each harness of 400 hooks, the first pattern is complete. Supposing there are 100 ends per inch or 2.54 cm. the pattern will accept 4 inches or 10.16 cm. and therefore, if cloth required is 28" or 71.12 cm. wide, there must be seven repeats of the pattern in the width of the cloth . All the repeats must be duplicated in like manner.

(iv) Thus , when one harness has been tied to each hook, beginning with the first and ending with the 400th , the first repeat is complete. In this manner, the second, third and till the seventh repeat are to be completed, always beginning from the first and ending with the 400th. Each of the 400 hooks will, therefore, have seven harness and seven ligoes.

In fig. 132B , diagonal lines, beginning at the same part in each section and running in the same direction throughout indicate a straight tie.

CENTRE TIE-UP:-

The centre tie-up is used when the two halves of any figure or birder are alike , when turned over. In all such cases a repeat of the pattern requires half the number of hooks to complete it. It has extensive uses for damask, upholstery, carpet and silk weaving. The center tue-up illustrated in figs. 133A and 133B Norwich system).

Fig.133A (top) Fig.133B (bottom).

The numbers in the line A represent the hooks in the jacquard. The first 400-threads are connected exactly like straight tie-up from back to front . When number one is arrived again . The same effect is obtained as in a point or V-draft in healds. The effect produced is really that of a figure on 800 ends , or twice the size of the machine. But the common practice is that the 400th and the first ends are not repeated to obtain a pointed effect in the design . In this case, when the 400th has been reached in the first repeat , the tie-up is reversed from 399th end to the second end in the next repeat from the 399th end to the second end in the next repeat. In a 400 Jacquard with center tue-up the effect of a figure actually obtained is on (400 x 2) - 2 = 798 ends. In the figure two repeats of the pattern are shown , but patterns are repeated as many times as are required by the design.

Border and Middle Tie-up:-

Fig.134A and 134B shows the method of tying-up the harness (Norwich system) firba bordered fabric, such as, sarees , table covers, bath sheets, handkerchiefs, etc. In these fabrics both borders should point inwards, as shown in the figures.

(i) The hooks to which the harness threads are attached to are numbered on the line A, and the tue-up begins in the left hand corner at the back of the comberboard (Norwich system).

(ii) The harness are tied-up for an ordinary straight over pattern for the first 400 ends , or one full repeat of the border and middle designs. 1 to 200 hooks being for the border and 201 to 400 hooks for the middle or body design.

(iii) But then , instead of commencing with the first hook again, the tue-up will begin from the 201st hook and end with the 400th hook. In this way, all the the repeats of the middle design will be completed, always beginning from the 201st hook. This forms the middle or body of the saree.

(iv) At the opposite selvedge, the first 200 hooks must require to be harnessed again from outwards to inwards to inwards of the fabric, as shown in the figure . Only two repeats are shown , but patterns may be repeated as many times as required.

(v) For border and middle tie-up , the figuring hooks are divided into two parts , some are used for the border weave, others for the middle weave. Again , the tie-up for them may be either straight or centre, or both straight and centre as required by the design. They are also known as ‘mixed ties’.

Compound Tie-up:-

The complex or compound ties are found in great variety and are useful and intelligent combination and re-arrangements of straight, center, or border, or mixed ties or drafts. The essential feature of a compound tie consists in dividing the harness into two row or more distinct section, each to control a different colour or count or to produce a different texture. For this purpose a comberboard may be divided longitudinally or transversely into equal or unequal parts, so that the mails of longitudinal division may govern all warp belonging to one section, as shown in fig. 135.

The figure is a plan of a compound tie in two unequal sections in the proportion of two couplings in A to one in B. The comberboard must be divided to correspond, as in the figure, in which the board has 12 holes to a row , and 8 holes of them form section A , while the remaining 4 holes for section B. With a 600' Jacquard, 400 needles may be used for one repeat if A, and 200 for B. Three for four sections can be formed in similar manner . In every case the leasing must bring the mails into their proper sequence. Thus in this figure the first of A is followed by the first of B, then the second and third of A are taken before the second of B, the and fifth of A are allowed by the third of B, and so on to the end. These kinds of compound ties are adopted for convenience to display different designs and various colours, counts or qualities of yarn in the same fabric.

Other compound ties save cards 50 percent or more , and are used for weaving compound fabrics, such as quilts, etc. which are stitched together in the loom. One example to weave such a quilting fabric will require 4 healds, which controls all the threads of one warp , and two comber boards, each containing half the remaining warp , threads. The healds and the comber boards are all actuated by tappets independently for the jacquard.

Ref:- Weaving Mechanism Book Vol.1 by Prof. N. N Banerjee.

Comments

Post a Comment