LOOM BREAK SYSTEM /TYPES OF BRAKE:-

Loom break system/Types of loom brake:-

A brake is device by means of which artificial resistance is applied to moving by in order to stop the motion of the loom.

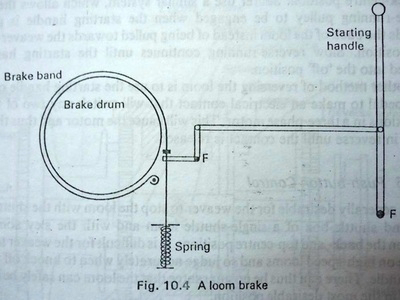

Fig of a loom brake.ref:- textileera blogspot.com.com

Types of brakes:-

Though there are many types of brakes, the following are commonly used in loom.

1. Shoe brake.

2. Band brake.

BAND BRAKE:-

The brake stops the loom immediately whenever required. The weaver uses it to stop the loom to repaire broken ends and picks.

A band brake consist of a flexible band of leather , or steel lined with frictional material which embrace a part of the circumference of the drum shown in the figure. One end is fixed at the point and the other is fixed with spring loaded collar. When force is applied to the lever hence the brake is applied. The friction between the band on the drum and the drum provides the braking force as lateral movement of lever creates a pressure on the brake band.

Ref:-https://textileera.blogspot.com

Loom break mechanism:-

To stop the loom by a weaver whenever required for repairing a broken end and picks immediately a brake stop motion is applied to the loom is known as loom break mechanism.

Image of electrical brake mechanism (Picanol delta Air jet loom)

CLUTCHES:-

A clutch is a form of connection between a driving and driven member in the same axis. It is so designed that the two members in the same axis. It is so designed that the two members may be engaged or disengaged at either by a hand operated device or automatically by the action of some power driven device . The common types of clutches which are used on weaving machines are;

1. Friction clutch.

2. Electromagnetic clutch.

(1) Friction clutch.

A friction clutch is used in the transmission of power of shaft and mechanism which must be started & stopped frequently as in the case of weaving machine. The force of friction is used to start the driven shaft from the rest and gradually brings up to the proper speed without excessive slipping of the friction surface. In operating such a clutch the following care should be taken.

a) The friction surface should engage easily and gradually bring the driven shaft upto proper speed.

b) The proper alignment of the bearing must be maintained & it should be located as close to the clutch as possible.

c) The heat generated due to friction should be rapidly dissipated and tendency to grab should be at a minimum.

d) Lateral displacement of the frictional clutch involves forces of high magnitude resulting in wearing of main shaft bearings. This can be avoided by using expanded clutch.

e) The surface should be backed by a material stiff enough to ensure the reasonably uniform distribution of pressure.

The friction clutches are of two types,

1. Disc or plate clutches.

2. Cone clutches.

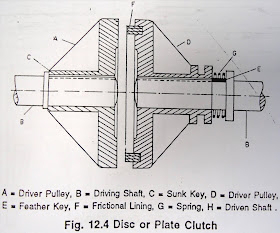

(1) Disc or plate clutches:-

In a disc or plate clutch as shown in the figure , the driver A is rigidly keyed to the driving shaft B by means of a sunk key C and feather key E , so that it can move along the shaft. The driven member is feed with a friction lining F & is held against a driven member by means of axial pressure provided by means of a spring. The axial pressure exerted by the spring provides a frictional force in the circumferential direction when the relative motion between the driving and driven member tends to take place. If the torque due to be transmitted, the no slipping take place and the power is transmitted from the driving shaft H.

Image of disc or plate clutch.

(2) Cone clutches:-

A cone clutch has a conical friction surface as shown in the figure . The driver which is keyed to the driving shaft by a sunk key has an inside conical surface or face which exactly fits into the outer side of the conical surface of the driven member . Like the plate clutch, the driven pulley is mounted on the shaft with a feather key & the two conical surface can be engaged or disengaged by means of starting handle through levers. The contact surface of the clutch may be metal to metal, but more often drive pulley is lined with felt or cork.

Ref:-https://fabricclub.blogspot.com

Comments

Post a Comment