Types of shedding mechanism (dobby):-

Types of shedding mechanism (dobby):-

(2) DOBBY SHEDDING:-

This is a compact, electronically guided shedding motion and capable of having up to 28 shafts. More complex and versatile shedding motion. A dobby loom, therefore can have upto 28 shafts, and much greater weave repeat is possible. Design may be woven with two or more basic weave, towels usually geometric design when pattern is provided by dobby.

Scope of of dobby:-

1.It can produce more complex design.

2. Theoretically it can control maximum 48 heald frame by practically 36.

3. For cotton yarn it can control maximum 48 heald frame .

4. Production is less than tappet.

Construction:-

In the negative dobby shedding the heald fames are operated by the jack lever. The levers are connected with the knife and the knives are attached with the driving rod by means of connecting needles. A pattern is used here according to the weave plan. When the teeth of chain are come to the contact of chain drum then the whole the arrangement moves together and lowering the heald frame is occured by spring.

Image of negative dobby shedding.

Working principle:-

The lowering of the heald frame is happens hereby spring or jack lever . When the pattern cylinder does not find peg on the pattern drum than baulk lever and jack lever bring heald frame in down ward direction, therefore the lowering of the heald frame is occured by means of spring tension.

Advantages of negative dobby shedding:-

1. Highly complex and critical fabrics can be weaved.

2. At a time , it can control many heald frame.

3. More faster than the positive dobby as well as over conventional loom.

4. Can produce close bottom shed.

Disadvantages of dobby negative shedding.

1. In this shedding only lowering of the shed is possible.

2. Due to more stress , yarn breakages more.

3. It is not good for heavier fabrics.

4. It does not provide more high speed to the loom.

Positive dobby shedding mechanism:-

In this type of shedding lifting and lowering of the heald both are possible, lifting is occured by means of jack & lever and lowering is occured by means of spring under tension.

Construction and working principle:-

Positive dobby is a combination of three cylinders, jack & lever, spring and shaft. Between the three cylinder a shaft is fulcrum in one side upper moves as the clockwise direction. The main cylinder when get motion from the shaft when it found peg or pattern plan , then the cylinder attached with the upper half toothed discs. So that the heald frame is up and when the pattern cylinder deos not found peg than the main cylinder attached with lower half toothed disc and the spring retains the heald frame to downward direction.

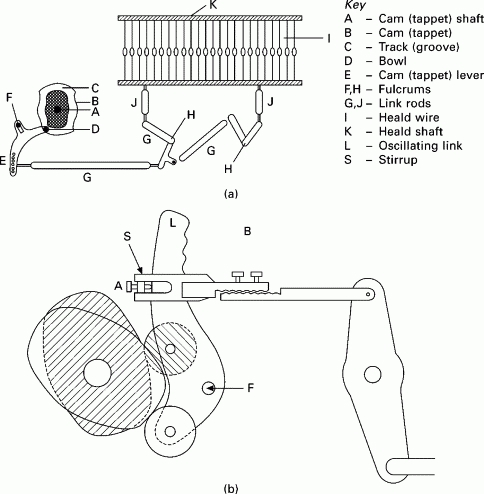

Main parts of a dobby shedding mechanism:-

1. Bottom shaft.

2. L-lever.

3. Upright shaft .

4. T-lever.

5. Upper draw knife.

6. Lower draw knife.

7. Upper hook.

8. Lower hook.

9. S-lever.

10. Bulk lever.

11. Thumb lever.

12. Jack lever.

13. Heald shaft.

14. Returning spring.

15. Motor.

16. Crank shaft.

17. Pattern cylinder.

18. Pattern chain.

Diagram of dobby shedding mechanism (climax dobby)

As shown in the above diagram it is a CLIMAX DOBBY . It is a double lift , double jack lever negative dobby. Here two jack levers are operated by a single bulk lever. They are joined with the bulk lever by a timber lever and link. The double lever is fulcrummed at point and is connected with S-lever. The S-lever controls two hook, one upper hook one lower hook. The are controlled by hook feelers. One hook controlled by hook feeler and another by a connecting needle. The two hooks control two knives that are joined with the T-lever. The T-lever is fulcrummed and is controlled by an up-right shaft and an L-lever. They get motion from motor and machine pulley. When the feeler comes in contact with a peg and when it is not in the contact it goes down.

Diagram Of Dobby peg plan.ref by printerest.

CONCLUSION:-

Dobby loom is important for its use. It can be used 8–12 heald frame in a tappet loom. If required to use more heald frame for more designs then we should use dobby loom.

Ref:-https://textilelearner.net

Comments

Post a Comment