WHAT IS SHED AND SHEDDING:-

What is shed and shedding:-

Dividing the warp threads in two layers ( sheet) for insertion of weft threads (pick) is called shed and the mechanism of this motion is called shedding in weaving. In weaving it is the first primary motion of weaving.

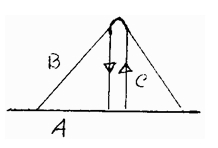

Image of shedding in weaving

In the above figure the shuttle is in the shed between the fel of cloth and reed.

Types of shed in weaving:-

There are four main types of shed which are as follows;

a) Bottom close shed.

b) Center close shed.

c) Semi open shed.

d) Open shed.

a) Bottom close shed:-

This type of shedding is produced by giving motion only to threads that are to form the upper line . Under this condition, the warp is level on the bottom line . Hence in order to form a top shed it is required to move some threads through a space equal to twice the depth of a shed, once up and down , before a fresh selection is made . A shed of this kind is known as stationary bottom with a rising and falling top.

Image of bottom close shed.

A-> Bottom line of warp.

B-> Rising and falling line.

C-> An arrow showing the space passed through.

Advantages:-

1. Alternate tightening and slackening the warp threads produce a covered cloth.

2. Produce fire fabrics.(silk)

3.Used in handloom.

Disadvantages:-

1. More stress or tension on the top warp line and less tension on the bottom warp line.

2. More chance of breakages on top warp lines.

3. Unequal warp tension produce poor quality fabrics.

4. Loom speed/weaving speed is slower.

5. Not possible to produce compact fabric.

6. More power consumption

7. More time required.

b) Center close shed:-

This types of shed is produced by imparting an upward movement to the topline of warp and the downward movement to the threads which are to form the bottom line of warp. Then after insertion of a pick , both the lines meet at the center between the highest and lowest line of divided warp.

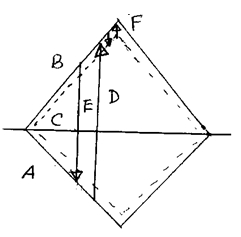

A-> Close warp line.

B & C -> Upper and lower line of divided warp respectively.

D-> Arrow showing the half distance of shed in a up ward direction.

E-> Arrow showing the half distance of a shed in downward direction.

Advantages:-

1. Equal tension on the top and bottom warp line.

2. Less time required so high production.

3. Less wear of the machine.

4. Less power consumption.

5. Less tear of the threads.

Disadvantages:-

1. Beat-up take place in close shed condition.

2. There is a chance of being moved backward.

3. Compact fabric can not be produced.

c) Semi-open shed:-

In this shed, the stationary bottom is retained but threads for the top line either passes to the bottom at one movement and again carried to top . In this shed close and open shed occurred simultaneously. In it the stationary bottom lines is retained, but threads for the top line either pass to the bottom at one movement, or are arrested mid way and again carried to the top, such as shed can be formed as expeditiously as an open shed, for the upward movement begins and ends with the downward through movement, and the arrested downward movement is converted into an upward movement immediately by falling threads are in the same plane as the using ones. They all reach the top to get together but the strain upon them is not equally distributed.

Image of Semi-open shed

A-> Stationary bottom line.

B-> Top point.

C-> The point where downward movement ceases in threads.

D & E-> Showing the movement of through Healds

F-> Arrow showing the threads which are to lift for the next pick.

Advantages:-

1. Equal tension on the top and bottom warp line.

2. All the warp yarns are not required to move up and down in every pick.

3. Beat-up take place in the cross shed condition.

4. The loom can run at a faster speed.

5. Possible to produce compact fabric.

6. Less complexity or disturbance in the shedding mechanism.

7. Used in power, dobby and jacquard loom.

8. For fancy fabrics.

9. Less power consumption

10. Less tear of threads .

Disadvantage:-

Useable movement.

d) Open shed:-

In open shed ,the warp threads form two stationary line , the top line and the bottom line and changes are made by carrying the threads fro one fixed line to the without any interval.

A & B -> Stationary warp line.

C & D Arrow which show the movement or rising and falling warp equal to distance between A & B.

Advantages:-

1. Beat-up take place in cross shed condition.

2. Equal tension on the top and bottom warp line.

3. The loom can run at a fastest Speed.

4. Extensively used in tappet shedding mechanism.

5. Basic fabrics (plain, twill, sateen) can be produced.

6. Less power consumption.

7. Less wear of the weaving machine.

Disadvantages:-

1. High warp breakage rate.

2. If higher no. of healds are used then the warp in back healds are more strained than the front ones.

3. Leveling apparatus should be added to open shed to place the heals in on plane.

Ref:-https://textileleaner.net.

Comments

Post a Comment