An introduction about shuttle less weavning (a non conventional weft insertion system):-

An introduction about shuttle less weavning (a non conventional weft insertion system):-

The weft insertion in the shuttle less weaving is carried out without using the shuttle. Since the pirn winding process does not occur in the shuttle less weaving methods to that the manufacturing cost is reduced the loom revolutions per minute are also increase comprehensively. The weft insertion in these looms is carried out from one side . The yarn package is directly used in weft yarn so that the loom stoppage time due to weft package change it reduced many times in comparison to the shuttle loom. The multi color weft fabrics is woven effectively . Eight colour in the weft may be used successfully in the projectile looms . There is no selvedge wastage in the projectile loom. The selvedge waste occur in the jet loom and rapier loom. Since the weft insertion is carried out from one side of the loom so that ordinary selvedge does not form in shuttle less weaving. Leno selvedge , tuck-in selvedge and melt selvedge are formed on shuttle less weaving.

The shuttle less loom can be classified into the below categories according to the weft insertion mechnism used in the shuttle less loom.

(1) Projectile loom.

(2) Rapier loom.

(3) Air jet loom.

(4) Water jet loom.

Ref:-https://www.textileadvisor.com

Apart from above looms there are also different types of shuttle less loom are coming later and their brief discussion under this heading.

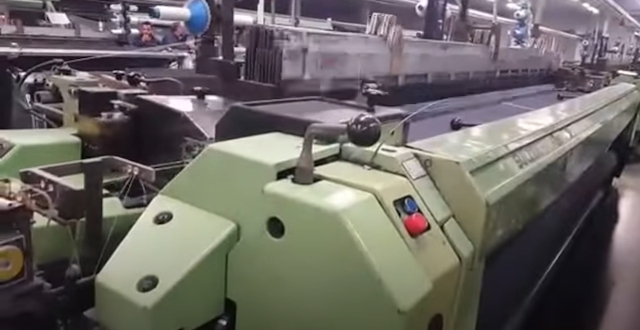

(1) Projectile looms or Projectile Weaving Machine:-

Projectile weaving machine is a shuttle less loom method for filling yarn insertion using a small metal device resembling a bullet in apperance with a clamp for gripping the yarn at one end , which then propelled into and through the shed. Among the types of my modern loom, projectile loom is one of them. The projectile weaving machine was introduced to the market in 1952 by Sulzer as the first successful, shuttle less weaving machine . In this weaving machine the weft insertion is carried out by small clamp projectiles , which number depends on the weaving width and which with their grippers take-out , the weft yarn from big cross-wound bobbins and insert it into the shed always in the same direction.

The unique principle of projectile filling insertion allows the insertion of practically any yarn , cotton, wool, mono and muti filament yarns , polypropylene ribbon and even hard fiber like jute and linen. This is because all yarns fine or coarse are successfully gripped and inserted by the projectile, resulting in a wide variety of fabrics , from simple staple goods through fashion cloth and from wide heavy industrial fabrics to jacquard clothes.

Main Parts of Projectile Weaving Machine:-

Major parts of projectile weaving (loom) are given below:-

(1) Torsion bar A:-

As shown in the figure 2, it has splinted ends as seen in the fig. one end is secured firmly at the clamping flange with provision for adjusting twisting angle . The twisting length of the torsion is 721 mm. Its diameter is 15 , 17 or 19 mm depending upon the model. Larger the diameter higher the initial projectile speed. The angular twisting of torsion bar at commencement of picking is 28–30.

(2) Picking shaft B:-

The free end of the torsion bar linked with the picking shaft through spines.

(3) Picking lever C :-

The picking lever is clamped on the picking shaft.

(4) Picking shoe D:-

The picking lever carries the picking shoe at its top end.

(5) Picking Shaft lever E:-

It is rigid part of the picking shaft.

(6) Toggle plate F:-

The toggle plates center at 0° carry a roller G and connected to the picking shaft lever E through a link H. They are covered at the bottom.

(7) Picking cam I :-

It is mounted on shaft J and rotates by bevel wheel K once every pick. It rotates in the direction of the arrow shown in fig. 2 It carries a roller R after the nose part

(8) Oil Brake L:-

The shock of the picking is taken by the oil beak .

Fig.2 picking mechnism in projectile weaving machine.

In the above figure 2 shown a picking mechanism in a projectile weaving machine where;

A= Torsion bar.

B= Picking shaft.

C= Picking Lever.

D= Picking shoe.

E= Picking shaft Lever.

F= Toggle plate.

G= Antifriction bowl.

H= Link.

I= Picking Arm

J= Shaft.

K= Bevel Wheel.

L= Oil break.

P= Projectile.

R= Projectile guide.

Working principle of projectile machine:-

Weft withdrawn from the package through a tension device, weft tensioner, shuttle feeder, scissor and weft end gripper. The picking arm has released the projectile which is shown in the guide teeth at the mid shed position. At the receiving side the weft end gripper is positioned to grip the weft after reception . The shuttle break is shown in its operating position with the shuttle returner ready to push to the projectile to the release and tucking position. Illustrates the torsion bar picking system of the machine . Strain energy is developed in the bar and released in such a way as to transfer the maximum possible strain energy to the projectile before it separate from the picker shoe.

The torsion bar (A) has its splined enda rigidly constrained in an adjustable housing with provision of adjusting the maximum angle of twist and Projectile initial velocity. The other end of the torsion bar is splined into the picking lever (C) which carries the picking shoe (D) at it extremity. The projectile (P) is illustrated in the shuttle lifter with the projectile spring opener. The bevel wheel (K) rotates the picking cam (J) which carries the picking arm (I) . The picking shaft lever (E) is rigidly connected to the torsion bar and through a short linkage to the toggle plate (F) center at anti-friction bowl (G). The action of the cam is for the smaller roller to bear against the toggle rotates it anticlockwise about anti-friction (G), thus withdrawing the picking shoe to it near most position. In the center of the toggle arrangement is in line and the torsion bar is twisted to its predetermined angle.

The nose of the picking cam then bears against the roller carried between the toggle plates and moves the control pivot of the toggle system offline center thus permitting the strain energy in the rod to be transmitted instantaneously to the projectile. The projectile separates from the shoes after 6.4 cm travel in 0.007s as a velocity about ,24.4 m/s after being subjected to maximum acceleration of about 6700 m/s (square) at a point 1.5 cm in board of the rest position. The residual energy in the picking system, some 62% of the whole is absorbed in the hydraulic buffer the body and plunger of which are shown at (L) .

Development of Projectile loom:-

(1) Colors Selection:-

(a)1x 1.2.4 and 6 colors can be used in weft direct.

(b) The system is freely programmable and operated by servo controler.

(c) No limitation on feeder position lifting.

(2) Electronic weft breaker:-

(a) This device keeps a uniform tension on weft.

(b) The braking force and the braking duration are programmable.

(c) Program can be given for each pick.

(d) The device is driven by stepper motor.

(e) Pre acceleration to the weft yarn is given by compressed air, which relieves extra tension in weft while inserting.

(f)K-3 synthetic projectile can be used for weaving delicate yarns

(g) The number of heald shafts operatable by cam motion is extend to 14.

(h) Speed has been increase upto 1400 mpm (470 rpm) due to improvement in many related mechanism.

(i) L.E.D display at single pole for machine ,speed , projectile arrival time, angle of machine stop, etc , which helps in monitoring process.

(j) Automatic weft brakes repaire motion enable shifting of feed package to a reserved one in the event of weft break between package and accumulator, no stopping of machine which increase the machine effectiency.

Advantages of projectile looms (machine):-

The projectile weaving machine offers the following advantages,

1) Low power consumption.

2) Reduced waste of filling material due to the unique clean, tucked-in selvedges.

3) Quick warp and style change.

4) Mechnical and operational reliability and ease of use.

5) Low spare parts requirement and easy maintenance.

6) Long life machine.

Another major advantage of projectile weaving machine is that more than one width of fabric can be woven at a time . Different width from 33 cm to 540 cm, make the projectile weaving machine even more economic, saving energy and space. Yet because of such weaving width wear and tear on the machine are also much reduced. Projectile weaving of machine can be single color or multi color machine for any sequence of upto four or six different filling yarns .

Disadvantages of Projectile Weaving Machine (loom):-

1. High initial investment.

2. Skilled personnel needed for initial set up .

3. Noiser , compare to jet and rapier loom.

Ref:-https://textilelearner.net

Comments

Post a Comment