Positive Take-up Motion in Ruti C looms:-

Positive Take-up Motion in Ruti C looms:-

In the Ruti C type loom the cloth is wound by means of the cloth beam against the take up roller. The density of the weft is set in three setting zones from 8 to 120 picks per centimeter of the cloth by interlacing the change wheel in take-up motion. The cloth beam doffs direct on to a transparent truck.

In fig.284 the centers of picking shaft wheel , driving pin L and the pick is coming from right. The take-up cam and the ratchet pawl are set in relation to the position of the crank at shed closing . If the shed closes at the top center of the crank, the take-up cam and the ratchet rod R are adjusted with the crank at the front center. Thus there is a difference of 90° between the shed closing and the take-up cam and the ratchet pawl setting. The engaging point of the ratchet rod R should be adjusted according to the following table :-

Table showing the combination of No. of teeth in cloth take-up ratchet wheel A, No. of teeth per stroke B and scale value respectively in positive take-up in Ruti C looms.

This positive take-up motion is illustrated at fig.285.

It consists of a train of wheel , namely,

(a) Ratchet wheel A,

(b) Change wheel D,

(c) Indexing shaft C-1,

(d) Change wheel pinion E, and

(e) Cloth take-up roller. The diameter of the take-up roller is 180 mm.

Fig no.285. of positive take-up motion.

With this arrangement of wheels and the diameter of cloth take-up roller being 180 mm. the teeth on the change wheel will have to be calculated according to picks per centimeter in cloth .

The take-up indexing gearing is for picks counts from 8 to 120 picks per centimeter recognisable either by the number of teeth of the indexing gear C-1 (14 teeth) and the change wheel pinion E (16 teeth) , or that of the auxiliary spur gear C-2 (28 teeth).

To obtained pick counts from 20 to 240 picks per inch or 2.54 cm. the cloth , other wheels remaining the same, the teeth in indexing gear C-1 will be 18 teeth, change wheel pinion E (16 teeth) or that of the auxiliary spur gear C -2 (36 teeth).

The teeth in ratchet wheel A are 62 and the number of teeth 1 or 2 per stroke is indexed B , shown in the table . The ratchet wheel A also have 64 teeth.

The sensitive let-off motion and the positively gripped take-up by means of a large felt covered draw roller give a good cover and ‘handle ' or 'feel' to the Ruti woven cloth. The diameter of the cloth roller is 570 mm, which assures long length of fabrics.

Positive let-off motion in Ruti C looms:-

The warp let-off motion and the back rest roller system in the C type weaving machine guarantee uniform warp tension from full to empty beam. Any fluctuation in tension are automatically compensated. A hand wheel is fitted for mannual adjustment. The back rest roller is adjustable with springs horizontally and vertically. This let-off motion is illustrated at fig. 286.

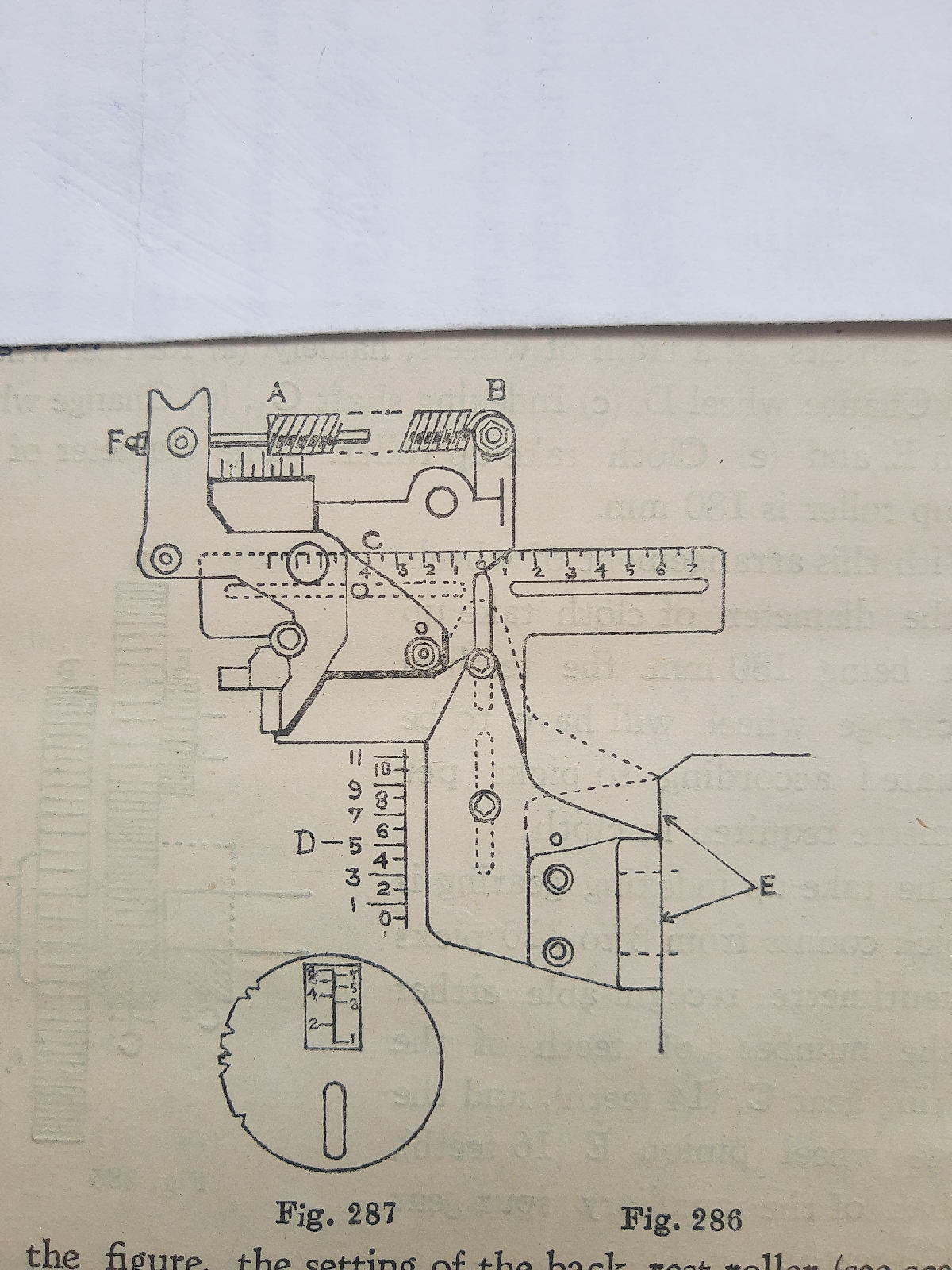

Fig. 286 & 287 of positive let-off motion in Ruti C loom.

In the figure, the setting of the back rest roller ( see scale) is adjusted to suit the wound diameter of the warp beam , by increasing or reducing the tension of the extension springs, A and B , or lengthening or shortening the transmission linkage F . The horizontal position of the adjustable support of the beam is shown at C , and the number indicates the direction of warp beam and weaver’s position.

The main scale readings D, from 0 to 11 facilitate the vertical position of the adjustable support of the warp beam . Scales also facilitate calculation of picks per centimetre or per inch or 2.54 cm. in the cloth , and is dependent upon the tension of the spring A . The top and the bottom position of principle support of the warp beam are shown by arrow at E. As the weaving proceeds , if it be found that the tension on the warp increases or decreases, then the lever arm of the let-off motion should be lengthened or shortened respectively.

The wide range of regulation for the tensioning of the warp can be extended by using an additional drag roller and hydraulic shock absorber, available with the machine. The warp beams with square shaft have maximum beam flange diameter og 800 mm. This warp beam diameter reduces the number of beam outs and cuts down on loom down time.

Pick Density:-

The throw of cam in the figure, gives eight picks: two gives 10 picks: three fifteen picks: four twenty picks: five twenty five picks : and six thirty picks per centimeter in cloth . The actuating pinion pin stands vertically under the center of the pinion.

Warp stop motion in Ruti C looms:-

A combined mechanical-electrical warp stop motion is fitted to this weaving machine. The warp stop motion is adjusted with the shuttle in the right hand box, and the position of the crank is 60° passed the front center. In this position the driving cam is adjusted so that the contact or sliding bars S have reached the extreme left position, as shown at fig. 288.

Fig.288.sliding patti of warp stop motion in Ruti C loom.

While the loom continues to run , the lever E is vertical, as shown in the figure 289. The torsion spring C is tensioned, so that during normal running the roller does not slip out of the groove of the segment. The contact or sliding bars work symmetrically; but when an end breaks and the drop wire falls down , the sliding motion of the bars S is stopped (fig. 288). The warp stop motion is then switched off, and the position of the lever E moves at F. The tappet loom stops when the crank in 30° before beating-up. The switching platelet is placed beneath the control switch . The disengaging lever is at B. The electronic-mechnical warp stop motion combined with brake and clutch drum of the loom ensures instant stopping of the loom at a warp break (fig 289)

Ref:-Weaving Mechanism Book Vol.II by Prof. N. N. Banerjee.

Comments

Post a Comment