Types of multiple box motion in (semi-automatic and automatic) power loom:-

Types of multiple box motion in (semi-automatic and automatic) power loom:-

NEGATIVE MULTIPLE BOX MOTION:-

(i) Diggle’s chain motion:-

The Diggle’s Chain is the most simple and is a combination of simple levers and a weft pattern chain, whereby the boxes are raised directly by various shaped bowls on the chain, but drop by means of their own weight. It is therefore a negative box motion and is of little use for fast running.

A diagram of Diggle’s chain at fig. 158 shows the simplicity of the action. The number of boxes used in this motion is either 2,3 and 4 . It may be possible to use more boxes.

A lever AC is centred at C, and the friction bowl B on this lever is moved upwards by a pattern chain composed of links fastened together on pins , which work round a barrel D. These are of different sizes , according to the number of boxes used. The smaller link leaves the top box in a line with the shuttle-race, and other links are of such sizes as to raised either the second, third or fourth box into this position. The general method is to raise the boxes one at a time and drop them all together, but this is not compulsory. When more than two boxes drop, there is considerable rebound . To remedy this, an extension is fitted to the back of the lifting lever AC, with suitable weight attached to help counterbalance the rebound of a falling box.

The method of turning the barrel D which carries the pattern chain is as follows:-

A wheel E, on the crank shaft S , drives a larger wheel F, above it. On the face of this wheel F, is a rim and two projection P P, or it may be only one projection. These projections or pins gear into the star wheel G, which is fastened to the barrel carrying the chain , and therefore when the star wheel is turned one tooth or one eight of a revolution, it will move the chain a space of one link.

The wheel E on the crank-shaft has often one-fourth the number of teeth contained in the wheel F . Therefore, if there are two pins or projections PP in the circumference the star wheel will be moved one tooth every two picks, and the boxes may be changed so often by making the chain T accordingly. The lever M which is centred at R, has the boxes attached to one end , and the other end may be pressed down by a foot of the weaver when it is required to lift the boxes for any purpose when the loom is stopped. Supposing the wheel E to have 15 teeth and F 60 teeth, if there are two projections PP , on the face of wheel F , the shuttle may be changed every two picks , but there is only one projection or pin , there may be a change every four or a multiple of four picks.

The chain becomes very cumbersome if a long pattern is required. To obviate this , the projections PP are in an improved motion, and are so made that they can be withdrawn from the gear with the star wheel. This is effected by a clutch motion. With this improvement, each link in the pattern chain may be made to represent any number of picks, the number being regulated by a small chain of metal card, and thus larger patterns may be made without the long heavy chain which are required in the ordinary 'Diggle’s chain.’

(ii) Knowle’s chain box motion:-

When compared with Diggle’s chain, Knowle’s chain is only comparatively negative in action . The rising of the boxes is effected by means of a chain which also serves to prevent a rebound when the boxes are lowered.

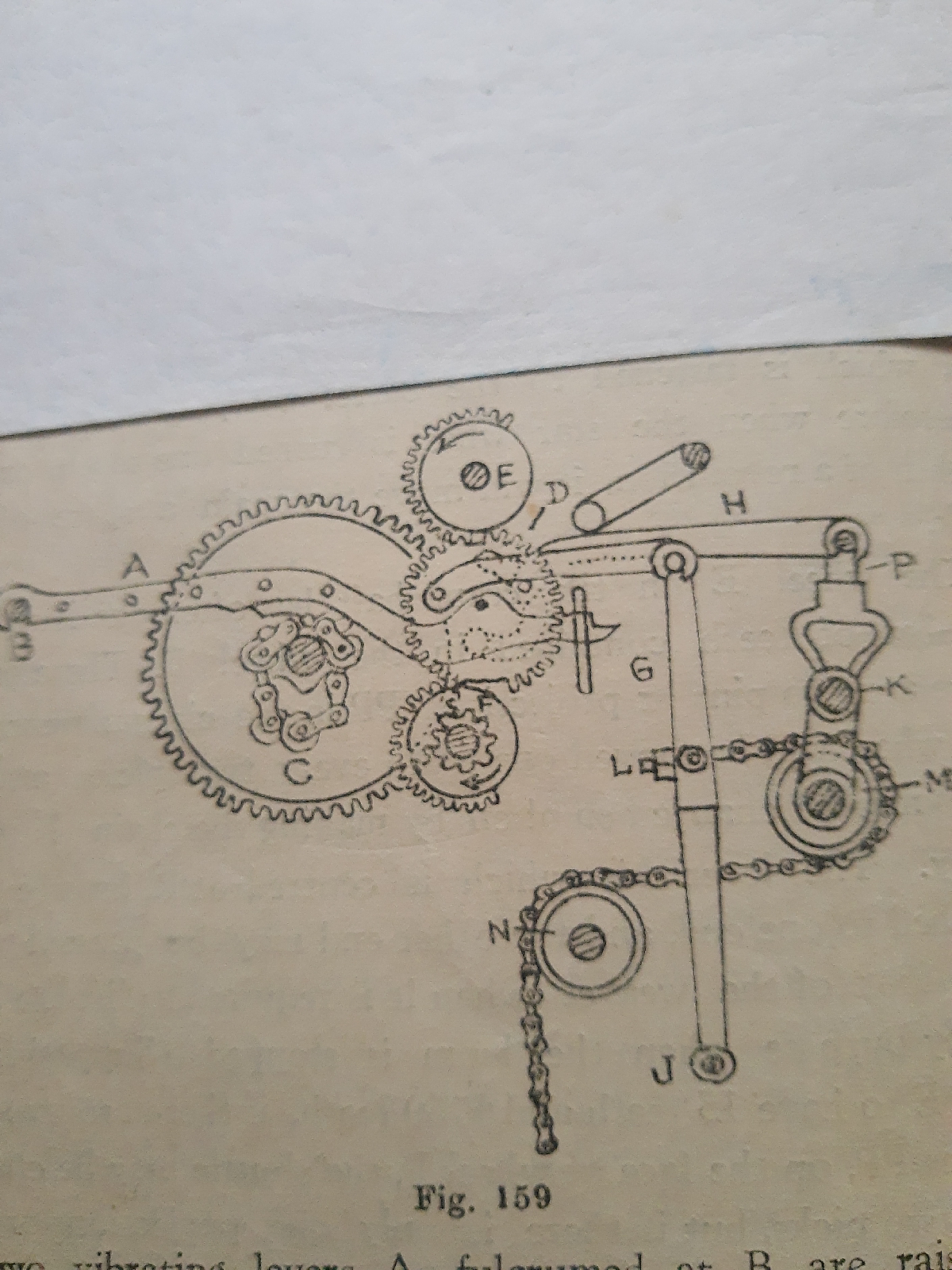

Another advantage is that the movement of the boxes being eccentric in character ensures a slow start leading to maximum speed in the middle of the action and ends in a final slowing down before the boxes come to rest . Knowle’s negative box motion is illustrated in fig. 159.

Two vibrating levers A, fulcrumed at B, are raised or lowered by link in the pattern chain C. At the other end of the vibrating levers are mounted the toothed vibrator wheels D, and the movement of the vibrator levers brings those into contact with either of the two fluted cylinders E and F. The fluted cylinders are revolving continuously opposite directions. Attached to the vibrator wheels D are two draw levers G and H. The lever G fulcrumed at J, has a lift of one box: while the draw lever H, fulcrummed at K, has a lift of two boxes. The lifting chain , attached to the center of the draw lever G at L, is carried over the grooved or flanged pulley M on the draw lever H and passes via pulley N and other pulleys to the box rod, ad shown at figure 160. For moving four boxes , two vibrator levers , two gears and two connectors are used.

Fig 160 Knowle's chain (negative multiple box motion)

When a vibrator wheel D is lowered into mesh with bottom fluted cylinder F , it is kept firmly in contact by a locking knife, actuated by a small cam on the spindle of F, moving over the tip of the vibrator lever A (see fig. 101). If the vibrator lever wheel is raised, the locking knife moves under the vibrator lever tip to keep it in place. Another steadying factor is a heavy swivelling bar that reacts on the top of draw lever H and G, and thus keeping them stationary after a movement has been made in either direction.

Positive Knowle’s Box motion:-

Knowle’s multiple box motion is also made positive in action on Dobcross looms by the duplication of the chain and pulleys. Thus one set of chain is used for lifting the shuttle boxes and the other set of chain is used to pull the boxes down, the boxes being controlled positively in either direction.

In this motion , the shedding, picking, taking-up and shuttle box mechanisms are connected and worked by similar parts from the centre. The cylinders E, F must have each , two sets of teeth , one for operating the shedding, the other for operating the shuttle boxes and picking; the latter segments are adjusted to permit the boxes and the picking to be timed differently from the shedding. (fig. 101).

Ref:-Weaving Mechanism Book Vol.I by Prof . N. N. Banerjee.

Comments

Post a Comment