Types of Picking motion (under pick & over pick):-

Types of Picking motion (under pick):-

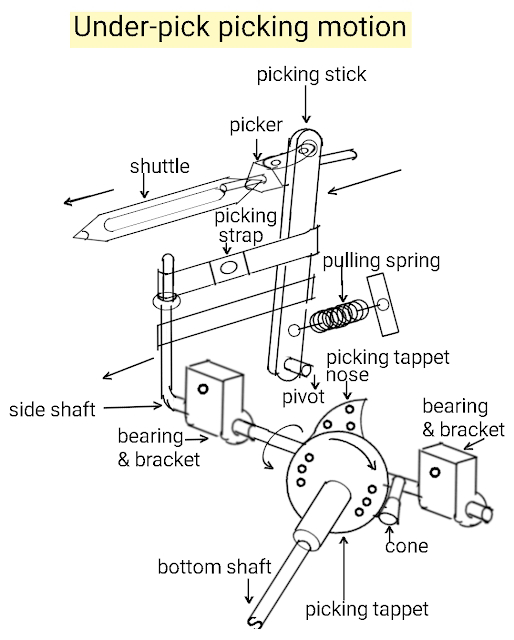

(4) Under-pick picking motion:-

Since the complete Picking mechanism is mounted under the loom in the motion and the picking stick also hits the shuttle under side of the loom , so that this mechanism is called under pick motion.

Structure and working of under-pick picking mechanism:-

The Picking is mounted on the bottom shaft of the loom.

The picking tappet is fastened on the bottom shaft with the help of a clamp and bolt. Picking tappet timing can be changed by the bolts and clamp. The tappet nose is mounted on the picking tappet with the help of bolts. The height of picking a tappet nose goes adjustable. A side shaft is used in under picking motion. This shaft can rotates in both the directions (clockwise and anticlockwise direction). The shaft is mounted on the brackets. A cone is mounted at one end of the shaft. The other end of the side shaft is an almost 90 degree angle . The other end is connected to the Picking stick with the help of a picking strap. The bottom end of the Picking stick is pivoted. The top end of the picking stick connected to the picker. When the crank-shaft rotates , it also revolves around the bottom shaft. The same picking mechanism is fitted at both sides of the bottom shaft. When the loom make two revolutions the crank-shaft makes two revolutions and the bottom shaft make one revolution only.

A picking tappet mounted on the bottom shaft gets rotated when the bottom shaft rotates. The picking tappet nose pushes cone mounted on the side shaft. Since the cone is mounted on the side shaft so that the side shaft is also rotated when the cone gets pushed downward. The inclined end of the side shaft is connected with the middle part of the picking stick with the help of a picking strap. The side shaft makes partial angular motion. When the side shaft rotates in anticlockwise direction it pulls the picking stick forcefully. The picker attached on the top of the picking stick hits the shuttle. Thus shuttle travels from one shuttle box to another shuttle box. Now the pulling spring acts immediately and bring the mechanism in its original position.

(5) Over-pick picking motion:-

In this kind of Picking motion the weft yarn is inserted into the shed from the overside of the loom. We can say in other words the picking mechanism which hits the shuttle over the side of the loom is called over pick motion.

Structure and working of over pick motion:-

The over-pick motion receives motion through the bottom shaft. This mechanism is fitted at both sides of the loom on the bottom shaft. A picking tappet is mounted on the bottom shaft with the help of a clamp and bolts. These bolts help to adjust the timing of picking. A vertical shaft used is connected to the foot step bearing. This vertical shaft passes through another bearing at almost the middle of the shaft. This vertical shaft can rotate in any direction. A cone attached in the slot of the vertical shaft . This cone is mounted with the help of stud and bolts. It can move freely in any direction. A pulley spring is also attached to the vertical shaft. A picking stick is mounted at the top of the shaft . An angular adjustment system helps to adjust the angle between picking stick and sley. A picking strap can be adjusted as per requirements. The other end of the picking strap is attached to the picker. The picker is made of nylon . The picker slides on the picking spindle . The shuttle rest in the shuttle box in front of the picker.

Working principle of over-pick motion:-

When the bottom shaft rotates the picking tappet mounted on the bottom shaft also rotated in the same direction. The cone mounted on the vertical shaft always touches the picking tappet. When the picking tappet nose touches the cone and pushes force fully, the vertical shaft receives angular motion. Since the picking stick is mounted on this vertical shaft , so the picking stick receives partial angular motion . The picker attached with one end of the picking strap hits the tip of the shuttle. Thus the shuttle travels from one shuttle box to another shuttle box taking weft yarn in it.

As soon as the picker hits the shuttle, the vertical shaft returns to its original position by pushing spring . The bottom shaft rotates at half the speed of the crank-shaft. One rotation of bottom shaft generates two picking cycle. This completes the picking motion.

Ref:-https://www.textileadvisor.com

Comments

Post a Comment