TYPES OF RAPIER LOOM:-

TYPES OF RAPIER LOOM:-

Rapier loom may have various types according to the weft insertion mechanism and number of picks. Such as insertion of double pick, insertion of single pick , two phase rapier etc.

Single Rapier Mechanism:-

A single, rigid rapier is used on these machines, rapier is a metal or composite bar usually with a circular cross section. The rapier enters the shed from one side, picks up the tip of the filling yarn on the other side and passes it across the weaving machine while retracting. Therefore a single rapier carries the yarn in one way only and half of the rapier movement is wasted. Also there is no yarn transfer since there is only one rapier. The rapier’s length is equal to the width of weaving machine, this requires relatively high mass and rigidity of the rapier to ensure straight movement of the rapier head. For these reasons single rapier machines are not popular. However, since there is no yarn transfer from rapier to rapier , they are suitable for filling yarns that are difficult to control.

Double rapier machine:-

Two rapiers are used in these machines. One rapier, is called giver , takes the filling yarn from the yarn accumulator on one side of the weaving machines, bring it to the center of the machine and transfer it to the second rapier which is called the taker. The taker reacts and brings the filling yarn to the other side . Similar to the single rapier machines, only half of the rapier movement is used for filling insertion.

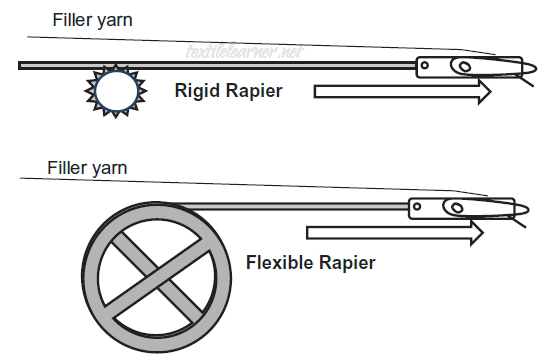

Double rapier machine can be a rigid or flexible. There are two types of double rigid rapiers . Dewas system and Gabler system. In Dewas system, the giver grips the tip of the yarn , brings it to the center and transfer it to the taker which retracts and carries the yarn to the other side of the machine.

In the Gabler system, the yarn in the form of a “U" shape to the center of the weaving machine. The yarn is than transferred to the taker , which extends the yarn to the other side of the weaving machine by straightening it. Since both rapier extended to the outside of the weaving machine, the space requirement for double rigid rapier machines is high.

In flexible rapier machines, the rapier has a tape like structure that can be wound on a drum . This saves space and allows narrower machine width compare to double rigid machines. The yarn is gripped both by the giver and taker . Double flexible rapier machines are more common than the rigid rapier machine.

Weft insertion mechnism of rapier loom:-

Rapier loom have an interlacing weft insertion system. The gripped head catches the yarn and from the feed bobbin and transports it through the shed . In the middle of the fabric the yarn is transferred to the opposing second gripper . The weft insertion is controlled at every single movement of the process. Therefore this principle is very flexible and extremely suitable for delicate materials. Rapiers are available in rigid and flexible forms.

Fig. 3;of Weft Insertion with rapier (courtesy Lindauer Dornier GmbH)

Insertion of weft by rapier is mechanically modern and refined version of the primitive method of fabrics production in which the weft secured in a slot of stick. At present version of the gripper head which are attached to rapiers which are the flexible type of the rigid rapier.

There are various types of rapier looms according to the weft insertion of double picks , Insertion single pick, two phase rapier etc.

In all rapier looms , to and fro movement of the rapier is derived from initially either from a linkage mechanism or from cam. The use of linkage mechanism has the advantages of simplicity, reliability and is cheap quite and consumes less energy than a cam mechanism but it does not provide any dwell to the rapier.

Single rapier loom can insert weft only on alternate rapier traverse. In many cases this is modified to achieve a higher rapier velocity in the early and late parts of the movement, thus maximum velocity half way through the movement. A useful feature of rigid rapier is that they can be simultaneously inserted in to shed one above the other as for producing double plush and certain carpets.

Due to high rate of insertion, the possibility of yarn breakages rate may increase . Additionally, it is necessary to control the weft by passing it through an effective tension arrangement so that the weaving tension will be more uniform, this can also reduce weft break.

The rigid rapier driven from the center and has a rapier head attached at each end. In one cycle of 360° the rapier insert one pick alternately in the right hand and left hand. The pick are inserted and beaten up in opposite phase.

Ref:-https://www.textilelearner.net

Comments

Post a Comment