Weaving of Multi Width fabrics on Ruti C loom:-

Weaving of Multi Width fabrics on Ruti C loom:-

Two Sets of Cam is placed for Weaving Multi Width Fabrics.

(1) The Ruti positive cam shedding motion weaves single width fabrics with one set of cams. It can also weave multi width fabrics with two sets of cams placed side by side.

(2) These two different sets of cams run independently at two different speed and offer a good range of weave possibilities. A spacer ring separates the first and the second set of cams. Both sets of cam have different lengths of supporting sleeve and bolt . The maximum number of healds actuated by these cams are 14 , which are used for one or two different weaves. At fig. 281 , the arrangement for one set of ten shedding cam C is shown.

(fig. 281. The arrangement for one set of ten shedding cam.)

(3) The spur gears A and B drives the shedding cams. After settling all the required number of cams , a spacer D is inserted for each cam omitted. Different lengths of bolt and cam supporting sleeves are used for cam setting . For 4 cams ,the length of bolt is 105 mm. and the length of cam supporting sleeve is 84 mm; for 8 cams these lengths are 177 mm. and 156 mm; and for 10 cams 213 mm. and 192 mm. respectively.

(4) The positive cam shedding motion may be combined with selvedge motion for 1:1 and 2:2 weave . When combined with center selvedge motion , not more than 8 heald frame can be used.

(5) The loop, that serves as a stop for levelling the harness frames, must not be shifted out of position, when cams are correctly set together for the weave . In place of positive shedding cams, the Ruti C type loom may also be mounted with dobbies or jacquards.

SHUTTLE:-

The shuttle design is new concept. The split type shuttle, used in the high-speed Ruti C type weaving machine , is of trapezoidal cross section, both front and back wall being 85" reed angle . It provides for a smooth flight of the shuttle and the life of the shuttle is also prolonged.

A lifting device of the swells a shuttle ejector make for easy handling. This split type shuttle takes a ringless bobbin. The bobbin remains always straight in the shuttle. Thus the weft breakages due to non-alignment of pirn in the shuttle is avoided . An efficient checking device by the shuttle protector checks the smooth boxing of the shuttle.

A single picking insertion is also provided in the loom. There is no lashing-in damage to cloth due to faulty transfer of pirn.

CRANKARM:-

There are two types of crank-arm, standard and short. The radius of crank for standard crank arms varies between 67mm. and 79 mm. and that for short crank-arm between 72 mm. and 82 mm. Shuttles used are 47–50 mm. and 53 mm. wide according to the number and size of the heald frames. The looms may be provided with or without selvedge motion.

The picking mechanism of the Ruti C type weavning machine is of a novel design, eliminating the conventional picking tappet.

PICKING MECHANISM:-

The picking mechanism of the Ruti C type weavning machine is of a novel design, eliminating the conventional picking tappet.

A smooth and gradual pick is achieved and is combined with a very efficient checking for the smooth boxing of the shuttle. The basic design of the loom eliminate the conventional crank shaft and picking shaft. All the main functional components run on anti-friction bearings.

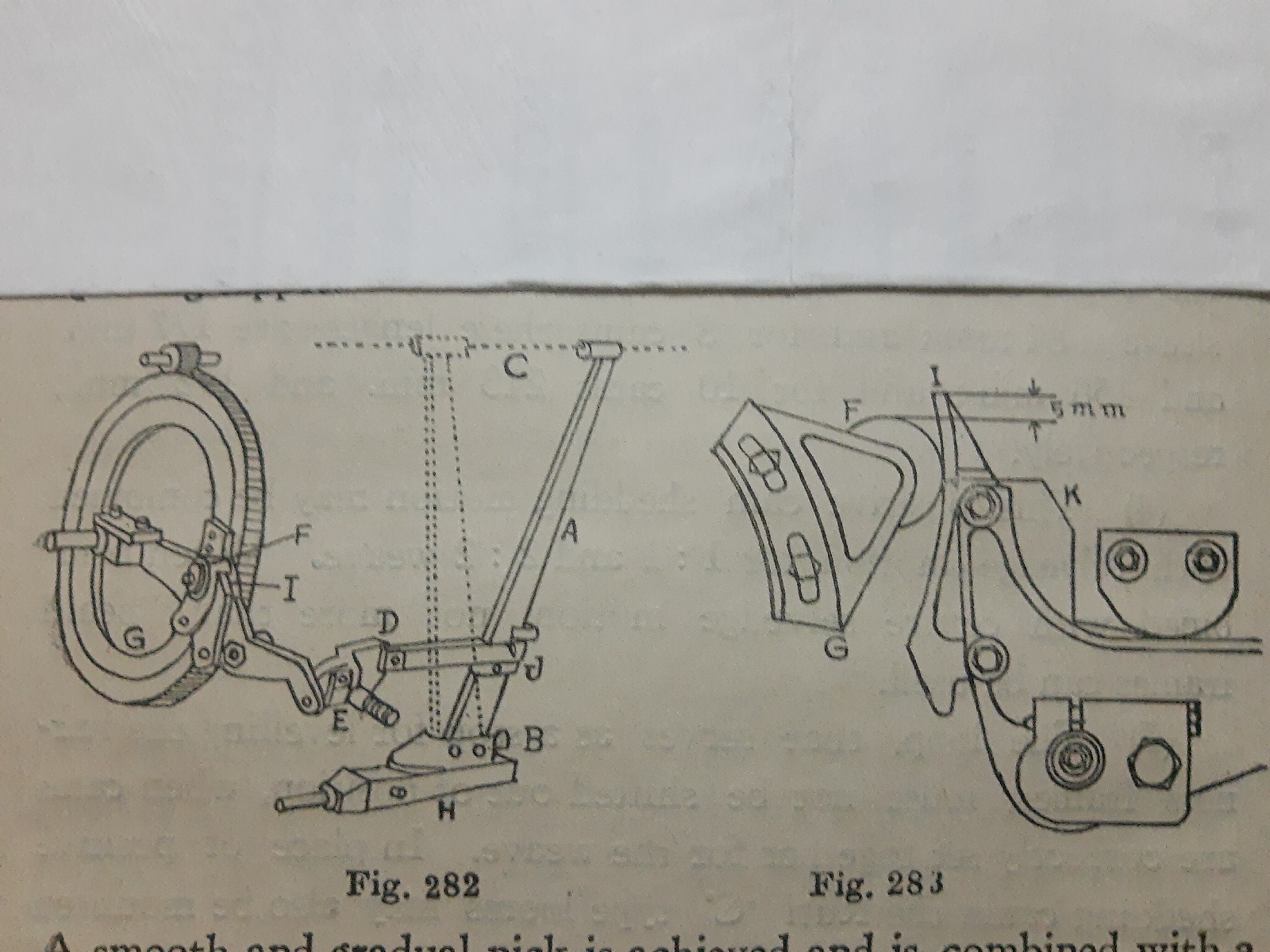

The picking system is sturdy, efficient and smooth. The figure, illustrated, is the adopted method of the under-pick motion used in this loom, as shown in figs 282 and 283.

As shown at fig. 282 , the Under-pick motion by means of picking bowl F and picking cam G, the flexible picking stick mounting S, the long picker path C , the parallel motion B on stand H, and special reed locking system help to give this loom it’s long and soft pick, and gradual shuttle braking. At D is the lug strap, supported on rest J, and at I is the picking curve. Before the pick begins, it must be seen that the picking bowl F contacts the picking curve I. Even at high speeds, dense fabrics upto 120 picks per centimeter can be woven.

The setting of the picking bowl is illustrated at fig. 283 . For standard and short crank-arms is picking curves I vary , and the correct picking curve is inserted according to the width of the weaving machine. The diameter of the picking bowl F is 70 mm. or 80 mm. When the diameter of the bowl is 70 mm, the upper edge of the picking bowl is set 5 mm. lower than the tip of the picking curve: when the diameter is 80 mm. the upper edge of the picking bowl fish is set with the picking cam.

Prior to starting the pick, the picking bowl F must contact the picking curve I. The pick begins at 45° of the crank passing the front center . At 3° before the pick begins, the stopping lever K is adjusted without clearance to the picking bowl, F. It should be noticed that the picking bowl must contact picking curve between 3" before and 1" behind prior to starting of the pick. A smooth and gradual pick is obtained, which is combined with an efficient checking device for smooth boxing of the shuttle.

SLEY AND REED:-

(a) In this loom , the bevel of the reed is set 85° to the sley , and the rib of the reed is set without play to the reed cap.

(b) With weft inserted and in open shed position, the shuttle guard stands one millimetre higher than the upper shed.

(c) The basic position of the reed is arranged to suit the width of the shuttle. For locking the reed, the torsion spring of the reed locking shaft is tensioned to suit the type of fabric.

(d) To stop the movement of the sley , the brake release lever is lifted , and the starting lever is put in, until the adjusting screw is against the brake release lever. This loom has the rigid sley cam motion .

(e) The various loom settings are done by dial readings , giving precise loom position rather than the conventional loom crank positions. Once the basic settings are done , and the loom is turned at beam fall , a trouble-free operation till the next beam ball results, with minimum attendance to the loom turning in between.

Ref:-Weaving Mechanism Book Vol. II by Prof. N. N. Banerjee.

Comments

Post a Comment