WINCH DYEING MACHINE:-

Features, Parameters and Working Process of Winch Dyeing Machine:

Winch Dyeing or Beck Dyeing Machine:-

The winch or beck dyeing machine is an old equipment used for processing fabrics in rope form. Besides, it is also the oldest form of piece dyeing machine. It is suitable for fabrics which can withstand creasing during rope form processing. In winch dyeing machine, the fabric is processed in the form of an endless loop. Winch applies a low amount of tension on fabrics during processing. During processing, most of the fabric remains submersed in a deep trough which increases material to liquor ratio (1:20 or 25) as compared to a jigger.

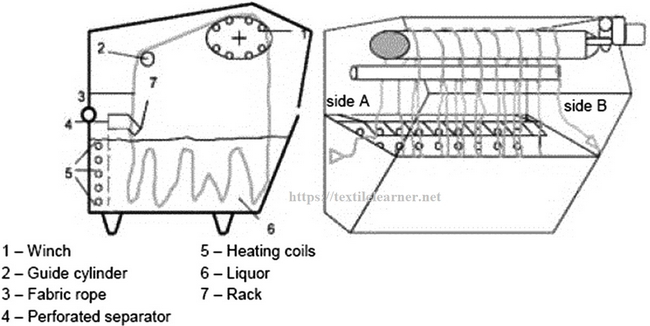

The construction of winch dyeing machine is comparatively simple and therefore economical to purchase & operate. It is suitable for practical all types of fabric, especially light weights, which can normally withstand creasing when in rope form as woollen & silk fabric, loosely woven cotton & synthetic fabrics, circular and warp knitted fabrics. This dyeing machine is used for fabrics in rope forms with stationary liquor & moving material. A winch dyeing machine consists of a vat (vessel) that has a curved back. Over the top of vat, extending its length is a horizontal elliptical winch rotated generally by an individual electric motor. In this machine, operations like scouring, bleaching, dyeing & washing can be easily carried out.

Winch can be classified ad follows:

1) Conventional winch dyeing machine

2) High temperature winch

3)High temperature winch with circulating liquor.

Features & Parameters of Winch dyeing machine;

Winch dyeing machine is a rather old dyeing machine for fabrics in rope form with stationary liquor & moving material. The machine operates at a maximum temperature of 95-98°C. The liquor ratio is generally quite high (1:20-1:40). Important features of winch dyeing machine are point out below.

1) The machine operates at a maximum temperature of 95–98°C.

2) The liquor ratio is generally quite high (1:20–1:40).

3) This is a dyeing machine for fabrics in rope form with stationary liquor & moving material.

4)In winch machines, a number (1–40) of endless ropes or loops of fabrics of equal length (about 50–100 m) are loaded with much of their length immersed in folded form inside the dyebath.

5) As for all forms of rope dyeing, the fabric must be fairly resistant to length ways creasing.

6)A perforated separating compartment, positioned at a distance of 15–30 cm from its vertical side, creates an inter space for heating & for adding reagents.

7) Heating can be supplied by means of direct or indirect stem heating.

8)The rope passes from the dyebath over two elevated reels. The first roller is free running (jockey or fly roller) & the second is winch reel.

9)The winch reel not only controls the rate of movement of the fabric rope, but also the configuration of the rope in the dyebath.

10) The winch reel does not grip the fabric positively, but by the weight of the wet fabric & the friction between the reel & fabric.

11) Now-a-days stainless reels with corrugated & broken surface for increase frictional forces are used.

12) The maximum motion speed of the fabric must be approximately 40 m/min.

13) The winch dyeing method is suitable for all fabrics, expects those which tend to originate permanent creases or which could easily distort under the winch stretching action.

A dyeing machine consisting essentially of a dye vessel fitted with a driven winch (usually above the liquor level) which rotates & draws a length of fabric, normally joined end to end, through the liquor.

Winch dyeing machines are a low cost design that is simple to operate & maintain, yet versatile in application proving invaluable for preparation, washing or after treatments as well as the dyeing stage itself. In all winch dyeing machines a series of fabric ropes of equal length are immersed in the dye bath but part of each rope is taken over two reels or the winch itself. The rope of fabric is circulated through the dye bath being hauled up & over the winch throughout the course of the dyeing operation. Dyestuff & auxiliaries may be dosed manually or automatically in accordance with the recipe method.

In loading a winch for dyeing operation, each length of fabric is run over the guide roll & the winch, so that the fabric falls in the vat at the rear end of the machine; the fabric is allowed to run over the rotating winch & get piled at the bottom of the machine; as the bottom is sloped towards the front of the machine, the piled fabric slides along it, acquiring a wavy shape & moves slowly towards the front end of the machine. When the free end of the fabric reaches the front end, it is picked up, passed between the pegs & stitched to the other free end of the fabric. Thus, the entire length of the fabric is now endless loop with much of it in a folded form at the bottom of the fabric winch. The winch is the prime mover of the fabric, but for the greater part of the dyeing period the fabric lies wholly immersed in the dye liquor.

Dyeing method with winch dyeing machine.

The basic principle of all winch dyeing machines is to have a number of loops or ropes of the fabric in the dye bath, these ropes are of equal length, which are mostly immersed in the liquor in the bath. The upper part of each rope runs over two reels which are mounted over dye bath. At the front of the machine, above the top of the dye liquor, is a smaller reel, which is called jockey or fly roller.

The fly roller remain free wheeling along with fabric rope. At the back of winch tank is the winch wheel, which pulls the fabric rope from the dye bath over the jockey reel for dropping in the dye bath for immersion. From the dropped location, the fabric rope travels back to be lifted & fed to winch wheel.

The dyeing process on winch dyeing machines is based on higher M:L as compared with other dyeing machines. The process is conducted with very little tension. The total dyeing time is lengthier as compared to other machines.

Advantaged of Winch dyeing Machine:

1) Construction & operation of winch are very simple.

2) The winch dyeing machines are suitable for types of wet processing operations from desizing to softening.

3) The winch dyeing machine is suitable for practically all types of fabrics, which can withstand creasing in rope form processing.

4) The tension exerted on winch is less than jigger dyeing machine, the material thus dyed is with fuller hand.

5) The appearance of the dyed goods is clean & smooth on winch dyeing machines.

Limitations/Disadvantages of Winch Dyeing Machine:

Batch dyeing operations needs trimming, sewing, opening out the rope, loading and unloading for individual lots separately.

Since several lengths of fabric are run over the winch reel into the liquor & sewn end to end, continuous length processing is not possible in a single batch.

Fabric is processed in rope form which may lead to crease marks, particularly in heavy, woven, thin & light synthetics.

Most of the machine work under atmospheric conditions.

Ref:-https://textilelearnet.net

Comments

Post a Comment