Manufacturing of khadi Fabric with khadi Machines:

Manufacturing of khadi Fabric with khadi Machine:

Khadi is a hand (home) spun and hand (home) woven cloth. Khadi is also called khaddar. It could be cotton, silk or wool. These fabrics are made entirely of biodegradable materials, without using finite energy (machinery) and resources, so their impact on the environment is greatly reduced. Unlike other industrially manufactured woven and knitted textiles, these fabrics are spun and woven by hand. Being hand crafted greatly reduces energy consumption, and furthermore has far reaching economic and social benefits to the artisans who produce the fabrics, living in remote villages. Khadi has historical importance. It is the symbol of the national freedom movement of India. Khadi was launched in 1920 as a peaceful weapon in the freedom movement of India by Mahatma Gandhi.

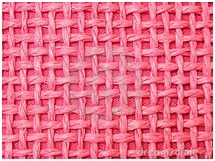

Fig: Khadi fabric.

The main uses of khadi fabric are as:

Ladies suit, Shirts, Bags, Bed Sheets, Dhoties, Jackets, Kurta Pajamas, Ladies and Gents Kurta, Gown, and Pillow Cover.

Manufacturing of khadi Fabric:

Manufacturing of khadi fabric is completely eco-friendly process. For making khadi fabric no need electricity. It is made with hand loom. Flow chart of khadi manufacturing is given below.

Flow Chart of Khadi Fabric Manufacturing:

Raw cotton is spun to yarns on the hand spinning equipment

↓

Yarns are wound to the bobbins or pirns as per the requirements

↓

In case of colored yarns, they are made into hands and taken for dyeing

↓

Dyeing is generally done with direct dye and auxiliaries such as soap oil, caustic soda, hydros

↓

Some of craftsmen even today prefer the naturally made dyestuff for dyeing

↓

After the yarn is colored it is winded and taken for the warping process

↓

Yarns are transferred by knotting process from the warp beams to looms

↓

Pit looms and frame looms are preferred for weaving khadi materials by hand driven, foot pedals and fly shuttles

Weaving process of khadi is discussed below:

Weaving is a method of fabric production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth is called weaving. The longitudinal threads are called the warp or pickings and the lateral threads are the weft or fillings.

Fig. plain weave cloth

This is an image of plain weave cloth in which we can see how weft and warp yarns are been interlaced at an angle.

Shedding:

Shedding is the space produced by dividing the warp sheet into two parts is called shed. We divide the yarn sheet by frames by up and down motion, they are set in such a way that one goes up and one frames goes down. Due to this yarn sheet splits up and the space we see is shed.

Fig. Shedding.

As we can see in this image the shed when the yarns sheets are divided up and reed also. Simply you can say that the dividing of warp sheet is shedding.

Picking:

Picking it is insertion of weft yarn in shed area is called picking. It is done by shuttle it passes from the shed area. Pirn is putted in shuttle and is set to the picker and it goes by applying force to handle which is connected with it.

Fig. picking

In this image we can see that pirn is in the shuttle and it passes from the shed area. Pick Length is the length of yarn used for 1 length is pick length.

Beating :

Beat Up is the displacement of pick yarn from shed area to the feel of cloth by either rolling or pushing up is beating up. The instrument which is used in beating up is reed which beats up the yarn when it is picked up from the shuttle and then reed is used to beat up and make fabric.

Fig.Beat Up

As we may see reed in this image that from where the yarns have been split up and from the shed area when picking is done this reed comes and beat up and this is the working of reed. Then it goes into fabric roll.

Working of Principle of khadi Machine:

1. In its working of yarn passage through Khadi is as under:

2. We add yarn in machine and pass it from the two frames which are set in a way that one is up and second is down.

3. The yarn is passed from eyes wire and then from the reed and then to the fabric roll.

4.There is a paddle which is under the frame and at the top of the frame you see ropes going up and due to fulcrum one frame go up and second down.

5) You paddle up and sown the frames will move and split up the yarns which are on the sheet.

6) This is will create shed area.

7) When the shed area is created the shuttle which passes from it and insertion of weft yarns in the shed area is picking. This is done when you apply specific force to the shuttle.

8) We see at the picker where shuttle is set there are ropes going up to the handle because of this handle you apply force and shuttle moves and goes to the other end.

9) After this process there is reed, after the yarn has been inserted we beat up the sheet and this process is called beating up and instrument used is reed. This is done by mechanically.

At then we take up the fabric and it is rolled.

Fig: Khadi weaving machine

By this process of yarn passage from khadi is achieved by insertion of wept yarns through shuttle in the shed area and beating up by reed.

Ref:-https://textilelearner.net & printerest

Comments

Post a Comment